|

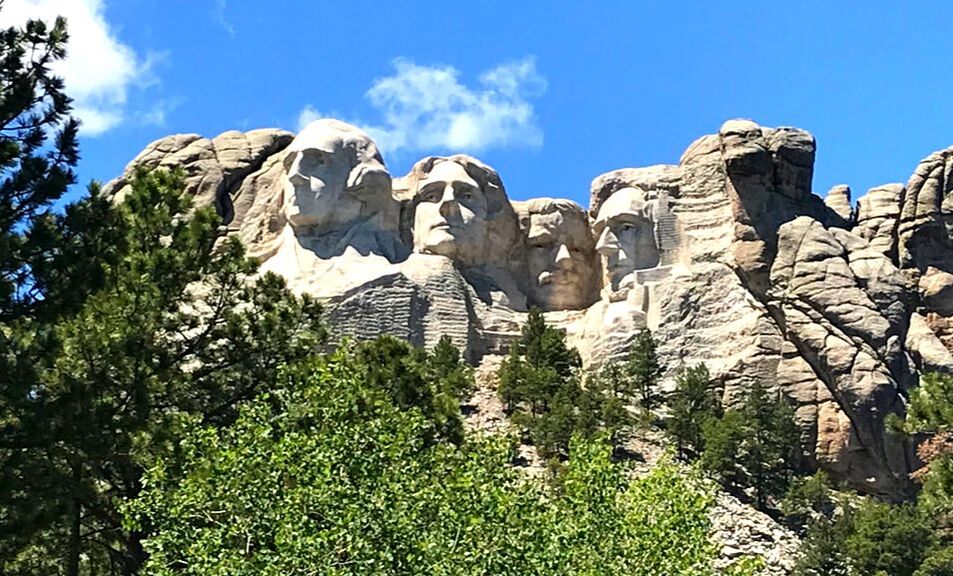

What. A. Month. It really feels like we crammed our entire summer into this one month. We have accomplished so much on the homestead with a little help from our friends and family—even Mother Nature did her part! Where to begin describing this shotgun of a month? The first week and a half of June is when about a dozen of Pete’s family members and some of their friends came up from the lower 48 to help with the giant laundry list of tasks on the homestead. Of course, we made sure to take a couple days off to show them some of our beautiful state with a glacier hike and some ocean fishing in Homer. In the middle of the month, our daughter and I went down to our home-state of South Dakota for a bit of a family reunion in the Black Hills. It was so nice to spend time with family and show our daughter some of my memorable vacation spots from when I was a kid. While we were gone, life on the farmstead expanded exponentially with our 50 meat chickens and 2 pigs arriving, not to mention all of the garden produce which we began to harvest. I squeezed in Wild North Design projects where I could, but going into this month, I knew WND had to be put on the back burner so we could focus our productivity elsewhere.  The Bacon Brothers arrived and are quite happy in their new home. They shared big piggy grins when Pete loaded their feed trough. The pigs spend their days rooting around and napping in the shade. We have future plans to expand their enclosure so they can 'root' up some brush for us, saving some back-breaking work on our end. I think the addition of the two meat pigs, we’ll call them the Bacon Brothers, was the most exciting event overall that happened on the farmstead this month. Though, if you ask me, the most satisfying accomplishment was completing the siding and soffits on the cabin! With only two days notice, Pete built a 10’x12’ shelter for the pigs that was made from salvaged metal roofing and extra logs. The pigs came from a new family farm in Willow. We are looking forward to eating some homegrown pork this winter after the Bacon Brothers are harvested in December. How to harvest these bad boys is still in debate. I prefer to take them to a butcher/processor, but Pete is leaning towards processing them himself. We have resources to do both, we will just have to see how busy we are when that time rolls around. We expect it will take at least two or three days to fully process both pigs by ourselves. We received our 50 chicks (broiler chickens) from the same Iowa farm as last year. When the chicks arrived in mid-June they were only 3 days old. I’m still baffled that these little creatures can spend their most delicate first days in a box whizzing through shipping terminals and riding on airplanes, but they seem to handle it just fine. As of this June, we still have about 4 birds left in the freezer from the 25 we harvested last August. This gives us sort of a benchmark we are able to use for how many chickens we consume in one year as a family. We plan to sell at least half of this year’s birds after they are harvested. We are excited to make them available and see how much interest there is in local, pasture raised poultry. The feedback we get will help us in deciding whether to order even more birds for next year, or dial it back and just raise enough for ourselves. After processing the birds between two days last year, we learned a few things we can improve on for this year’s harvest. The first improvement we have made to our chicken operation this year is separating them out into multiple enclosures which can easily be moved onto fresh grass each day. So far, these new mobile enclosures have been a success! The chicks are very comfortable in this new set up after they moved out of the Eggcono Lodge at two weeks old (after their feathers started to come in, called fledging). There was a noticeable change in temperament after only a couple hours in their new enclosures. Instead of being in one large group, stepping on each other and fighting for access to the feeders, they now spend their days “hunting” bugs and stretching out in the grass, with the occasional meager attempts at flight. Another benefit to the outdoor mobile chicken runs is how they work the ground; nibbling down the grass and turning it, and the bugs they find, into manure. Last year, we left them on one patch of grass the whole time and continually added straw for clean bedding. That method left us with lots of straw and manure to use in the compost, but there wasn’t much incentive for them to move around much and it didn’t take long for them to eat all the grass in that area. This summer, it is easy to see where the chickens were last year; just look for the ultra tall, vibrant green grass! Our strategy for this season is to spread out that benefit for the soil over as much of the field as possible. Our second big improvement to our poultry operation is a machine for plucking the feathers at harvest. We plucked those chickens by hand our first year and quickly recognized that this process was the longest, most tedious step in the entire process. We can fit two chickens in the machine at a time and they should be completely plucked clean in under a minute. Compare that to the 20+ minutes we spent plucking a single chicken last year, and, well, I’m very excited to try out this new time-saving tool! And a third new addition to help with the harvest is an open air lean-to behind one of the greenhouses. This new covered area will serve as an ‘outdoor kitchen’ which will allow us to efficiently process meat and garden items. Of course, it’s vital to keep clean and separate workstations for processing meats and vegetables. We plan to add a sink and more counter space this summer to aid in the processing. The lean-to will also be a perfect covered storage for the garden tools and supplies, keeping them closer to the field and also freeing up space in the garage. We have been putting the makeshift kitchen to good use for cleaning some of the early vegetable harvest. Speaking of vegetables, the garden beds & greenhouses have been very productive. It has been amazing seeing how fast things grow under the nearly 24 hours of light. This month, Pete harvested one of his first plantings of beets, yielding nearly 20lbs from the 50 seedlings he transplanted about a month ago. Many of the beets will go to the pigs and chickens this year, but we will save some for ourselves for beet juice and general food items. This gives us a chance to observe our harvest process and the impact it has on shelf life. For instance, we are curious about the impact of cutting off the greens before storage. Vegetables lose most of their moisture through their leaves after harvesting, but it is more appealing to sell fresh beets with the greens still attached. Not to mention, the greens on beets are also edible. So we are doing a lot of experimenting this season to find the best ways to harvest, store, and ultimately sell the produce. While Pete’s family was here helping, his mom, a fabulous green thumb, helped transplant many of the seedlings Pete had started in the nursery greenhouse in May. She transplanted 50 pepper plants, another 150 red and golden beets, and 50 nasturtiums. She also direct-seeded a second bed of about 750 carrots. After their first few weeks of transplanting, all the vegetable plants are doing great! The lettuce has been growing much faster than expected inside Greenhouse #2. We are finding we can go from seed to harvest in about 4 weeks using the greenhouse, and we can easily get a second harvest within one week of the first cutting. All this lettuce coming so fast kind of caught us off guard, since we have yet to get our salad greens processing station set up. We’re realizing that washing, drying, and packing salad greens takes a separate, more specialized setup than for the fruits and root vegetables. More planting and growing is planned throughout the summer as we get our processes dialed in. We are excited to see how things grow into the unpredictable Alaskan fall season. After a year of chasing away dogs and ravens from the compost piles, Pete has stepped up our composting operation and built dedicated bins for making compost in the garden. Although most of our kitchen scraps go straight to the pigs and chickens during summer months, we still find plenty of organic material to contribute to the compost. It’s amazing how warm the compost gets – nature in action rapidly breaking it all down into plant food. Pete regularly waters and re-mixes the compost in the bin to ensure proper decomposition. At our previous home, we had experimented with making compost tea which is like a plant superfood. The runoff from the compost serves at the base for the tea. Hopefully we can start making compost tea again in the future! One of my favorite accomplishments this month was the siding & soffit on the house with a railing on the deck. No more Tyvec house wrap! Our house looks more like a finished home now, and less of a construction site, which does wonders on my mind. The friends and family that came up worked very hard on these projects and I am so grateful for their efforts. I won’t bore you with the designing and color choices that was all 100% my decision, but I will say that it’s harder than it looks! We didn’t quite have enough time to finish the painting of the trim because we had to wait for the rest of the paint to dry. Though the days had been very hot and dry, the night time temps were still dipping into the mid 40°s with nearly 100% humidity. This caused it to take about 2 weeks for the entire house to dry completely. We kept testing the sides with our fingers before the crew left hoping we could squeeze in the finishing touches on the cabin. The siding now has everyone’s fingerprints and the occasional mosquito and some sawdust permanently imprinted on the side —I love it! The railing on the deck was a ‘bonus project’ meaning it wasn’t on the list, but it was quickly designed and installed while the crew was here. The railing is a lovely design is exactly what I had in mind. It’s practical and durable, withstanding a toddler & Mother Nature. Speaking of our toddler, another bonus project was a timber swing set, which looks great! We will stain the deck to match as soon as we have a day where we aren’t running in and out of the house—maybe in the fall during hunting season? Another one of what I call “Missy Projects” was also checked off the list this month: a garbage bin. Every month or two we have to make a trip to the local dump to get rid of trash. This newly constructed bin will give us a spot to store garbage before we truck it away. We are planning on making a rocket stove type burn barrel to burn most of our trash, but there are strict burn bans for much of the summer around here, which we are happy to comply with. With a big burn barrel setup, we can get rid of most of our trash on site, at least in the winter months, which will cut back on our trips to the dump. Not the most glamorous topic, and not something I had really thought about before moving here. Goes to show I took for granted the convenient weekly garbage and recycling service in the lower 48! We do have a camera watching over the garbage bin, in case it lures in any critters. Bears have been less and less of an issue around here in recent years (likely due to poaching), but we still remain mindful of the wildlife around us even if we don’t see it very often. *Sidenote about the burn bans: it's been another hot and dry summer, third one in a row. So far at the end of June, over a million acres have been burned from wildfires this year alone in Alaska. It's mostly tundra acreage, but we still need to be cautious. We have experienced lots of hazy and smoke filled skies in the mornings lately. The fires are almost all started from random lightning strikes which is a natural phenomenon of nature burning old growth. After a change of pace for a month, we are getting back to our usual routine. Wild North Design will be back to doing markets at the JBER Army/Air Force base this summer and looking to get my foot in the door at other summer Alaskan markets. One of the pieces I was able to complete this month was a custom sign for a local business and boy, am I impressed with myself! This was the most complex resin piece I have done so far. I’ll use the rest of the summer months to build inventory and work on new designs for the upcoming holiday markets this fall. Stay tuned on social media to see what we come up with! As June comes to a close, July quickly takes its place. July brings the salmon run which is like a floating holiday for Alaskans. When the salmon are running, we drop what we’re doing and head towards water! It’s a fun time of year and a great excuse to put projects aside for a few days and get some fresh salmon in the freezer. We’re also looking forward to finding some new blueberry patches for the August harvest while Pete will be experimenting with new crops for a fall harvest. I’m no meteorologist, but I predict July will be hot and sunny, and occasionally cool and rainy. Check back next month to see if I’m right :D Thanks for reading, Everyone!

0 Comments

Leave a Reply. |

AuthorHello, I am Melissa, owner of Wild North Design. Recently, my husband and I decided to pick up and move to Alaska. This dream has been a couple years in the making and we are enjoying the journey so far. We love to learn and make all kinds of things. From wood craft, to painting, to vehicles, landscaping, building, exploring...we love it all! We are finding out that Alaska is a great fit for our restless minds and bodies! Excited for what the future holds for our expanding family! Archives

January 2024

CategoriesThis website uses marketing and tracking technologies. Opting out of this will opt you out of all cookies, except for those needed to run the website. Note that some products may not work as well without tracking cookies. Opt Out of Cookies |

|

Shop

Wedding Decor Toys All |

RSS Feed

RSS Feed